The Department of Computer Science and Control Systems at ITMO University houses a robotics lab. In this article we’ll take a look at the projects its staff is working on, and show you the machinery on site: industrial manipulator robots, robotic hands and dynamic positioning system testing equipment.

The robotics lab opened its doors in 1955, as the university’s oldest department — the department of computer science and control systems — reached its tenth year of operations. Originally it was used for the development of automated ship testing equipment. Later its staff ventured into cybernetics, CAD and robotics.

Today, the lab staff is primarily preoccupied with the development and enhancement of industrial robots. Man-machine interaction is of particular interest: robots capable of working alongside humans, and new, safer methods of robot control, are being actively developed.

Remote control and online automation systems are also on the lab’s proverbial radar.

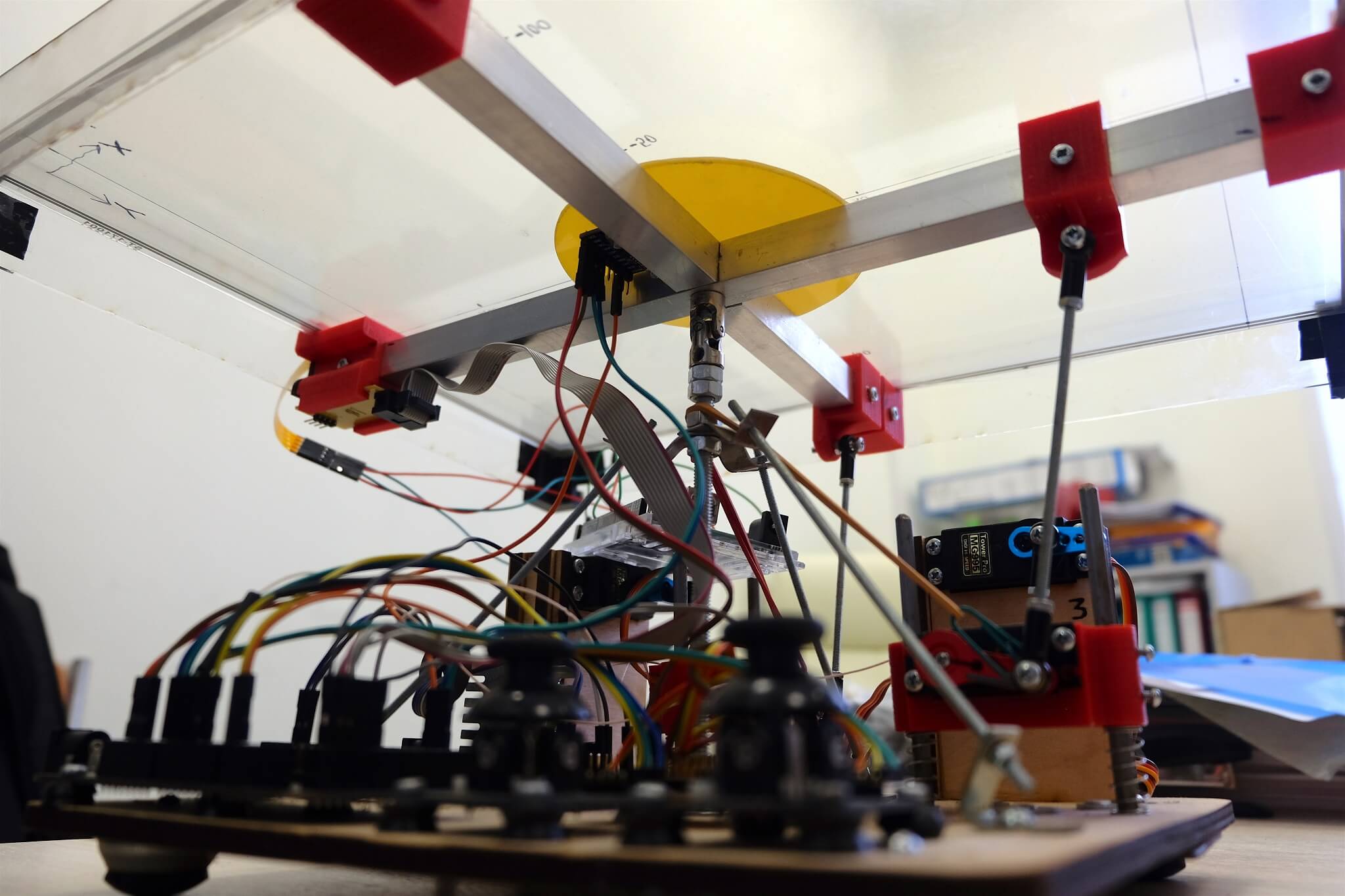

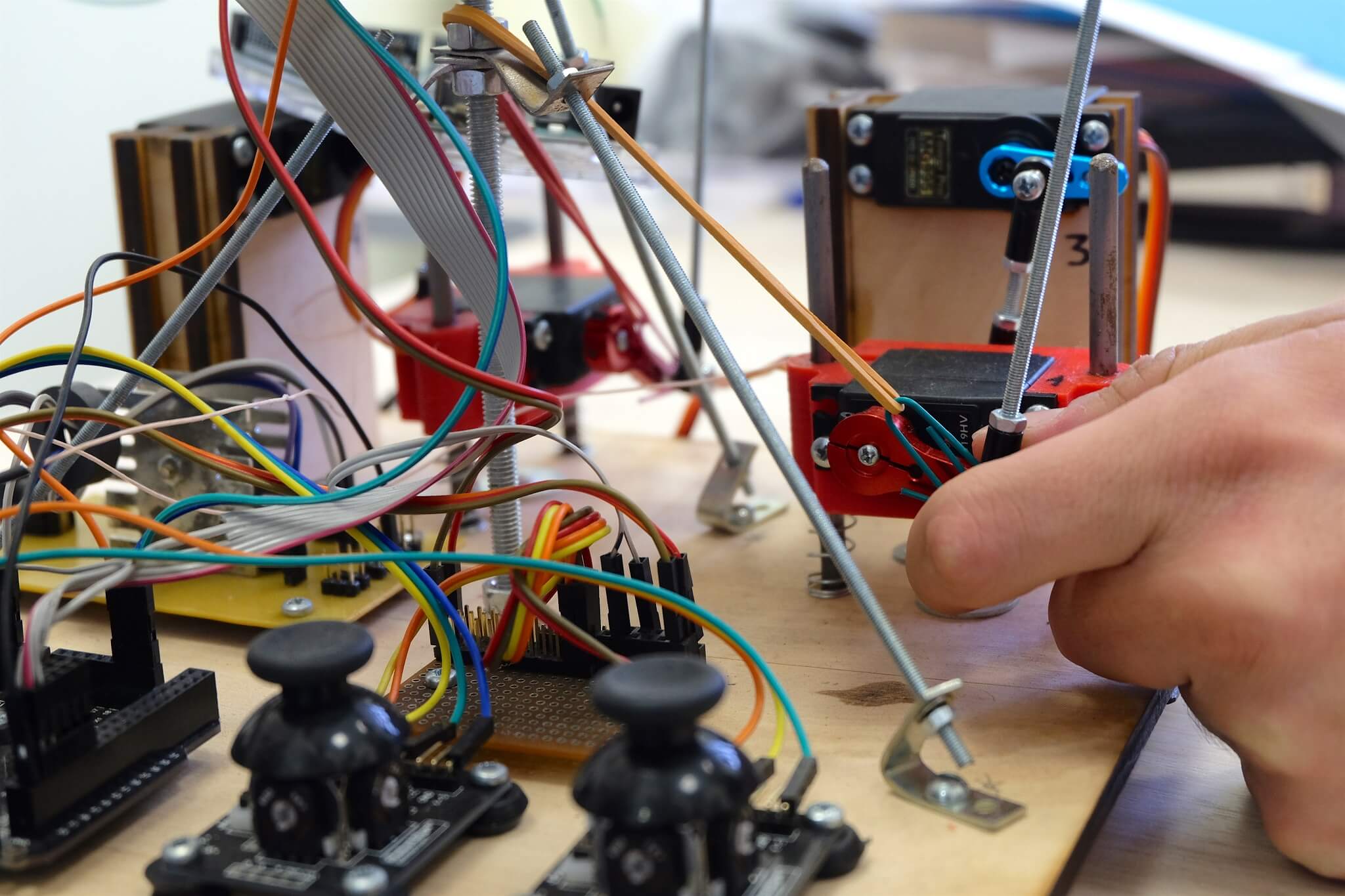

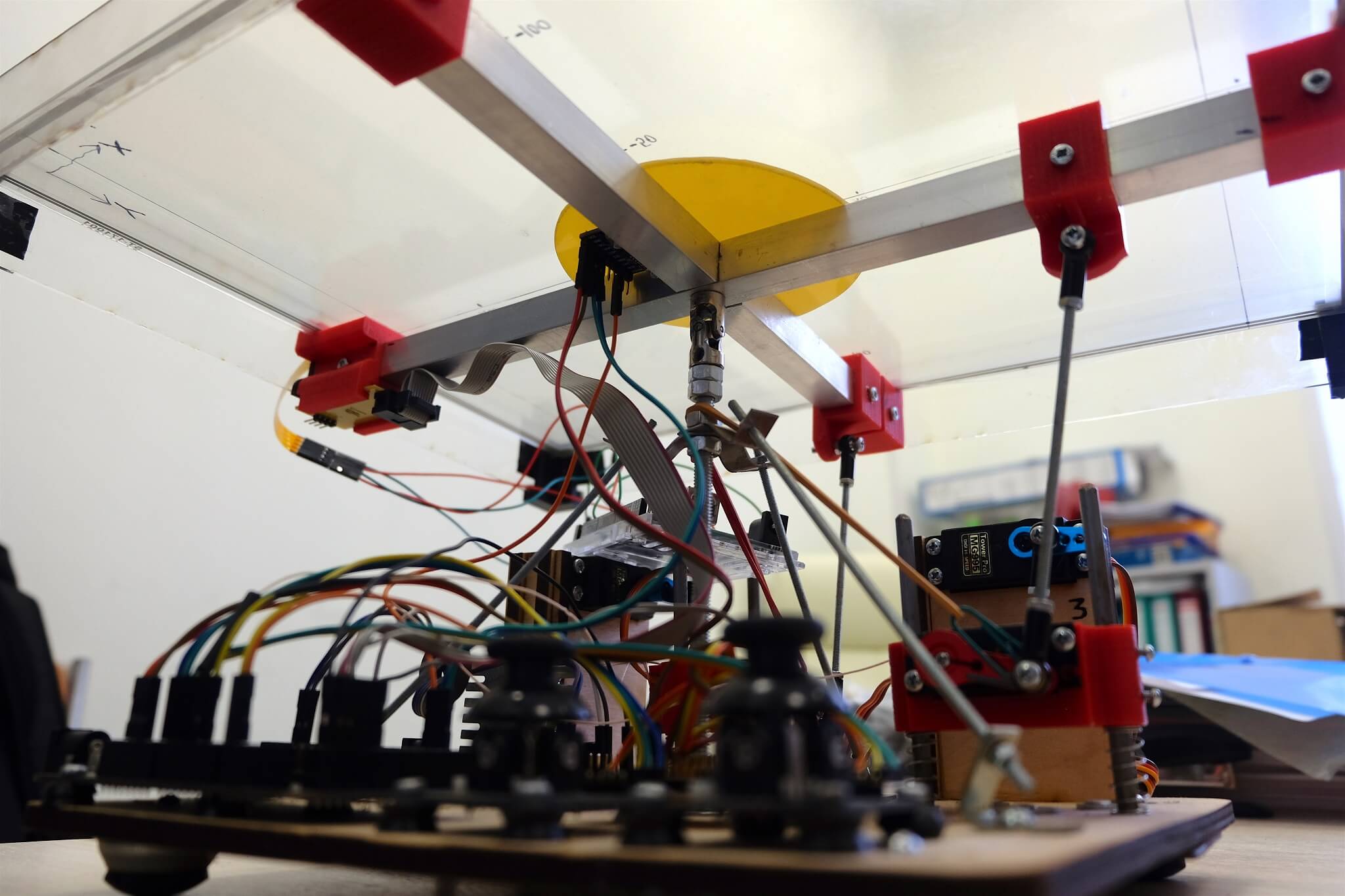

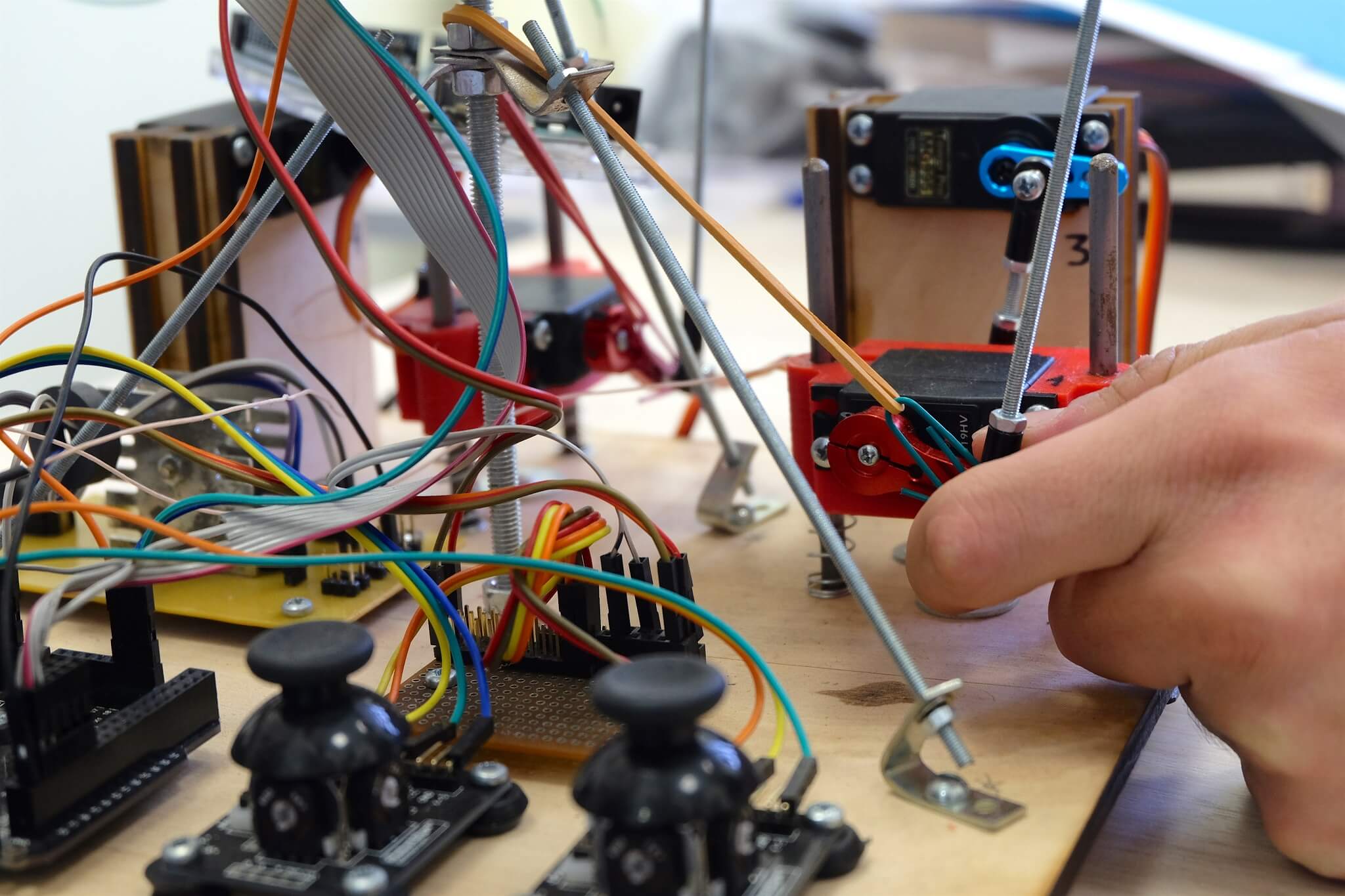

Some of the lab’s industrial robotic equipment was purchased from large companies. The rest was created in-house, like this 2-DoF Stewart Platform. You can use it (video) to work on balancing algorithms.

The Stewart Platform sports a rectangular sensor-fitted surface the angle of which can be adjusted via USB. It detects and reports back the coordinates of the objects placed upon it. The goal of the operator is to develop an algorithm that keeps the ball in place despite the movement of the surface.

To ensure accurate results, a set of automatic motors compensates for external interference from vibrations or wind. Another lab machine worth mentioning is the KUKA youBot mobile robotic arm.

It was used (video), in conjunction with a digital camera and image processing software, for the testing of object tracking algorithms.

To eliminate outside factors, all external interference is being measured and compensated for. The end result is fascinating — the arm is capable of steadily holding tools and correctly moving them alongside a set trajectory.

The arm was used in an interesting international project. Torque sensors are expensive — so we partnered up with TRA Robotics from the UK to develop a sensor-less torque measurement system. As a result, we can gather data on robotic tools’ interactions with the rest of our equipment without investing extra money or using extra machinery.?

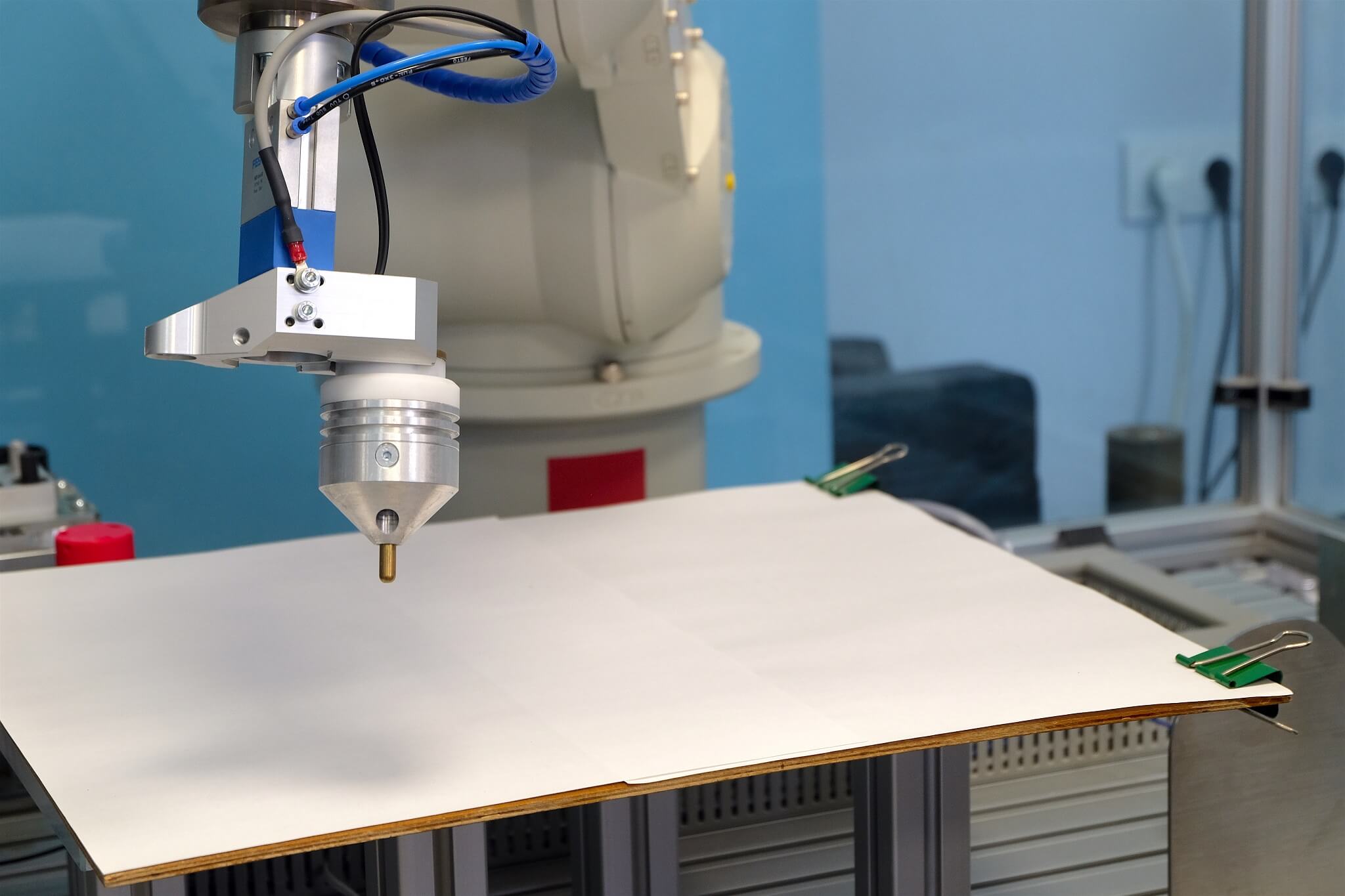

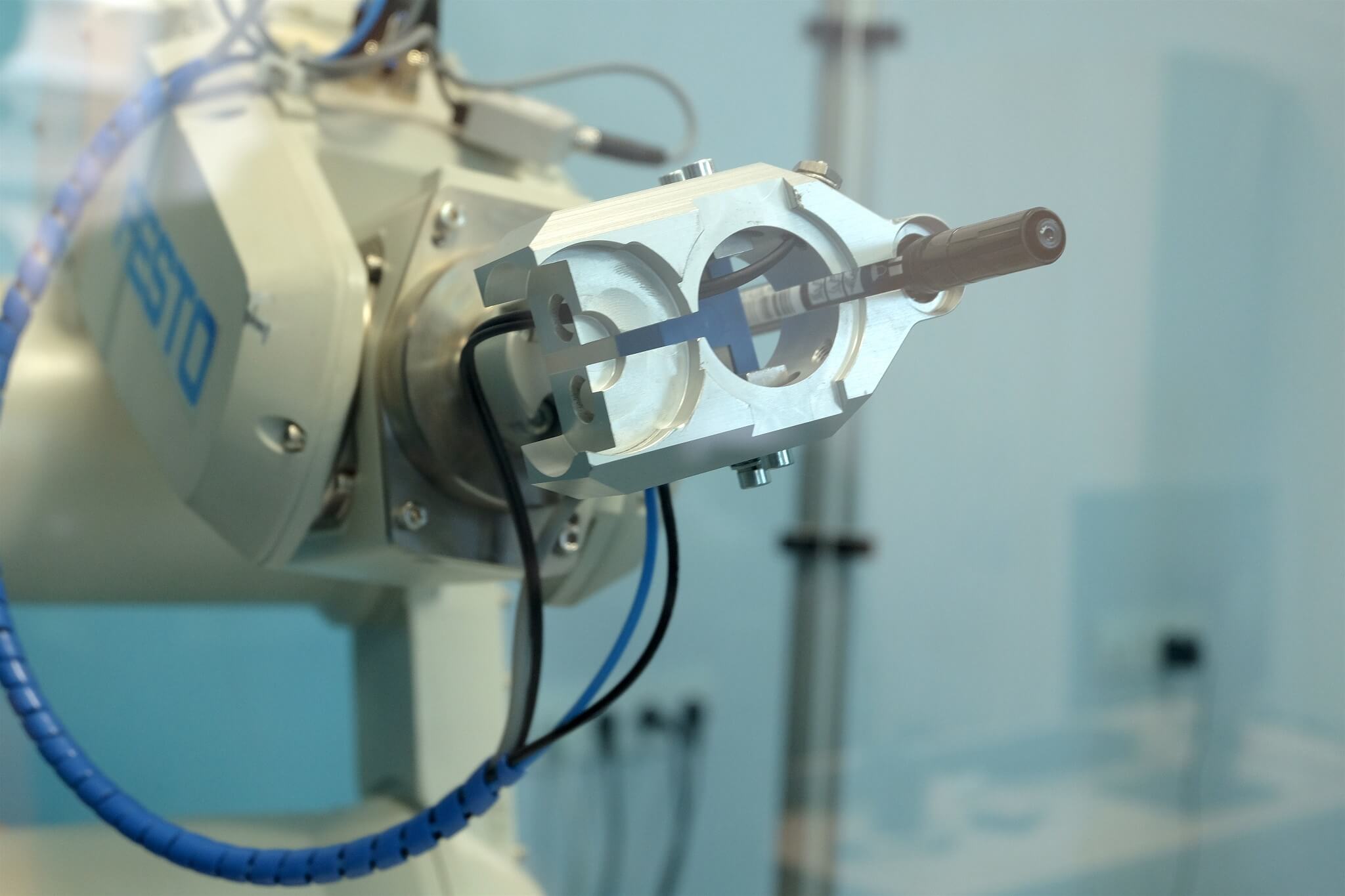

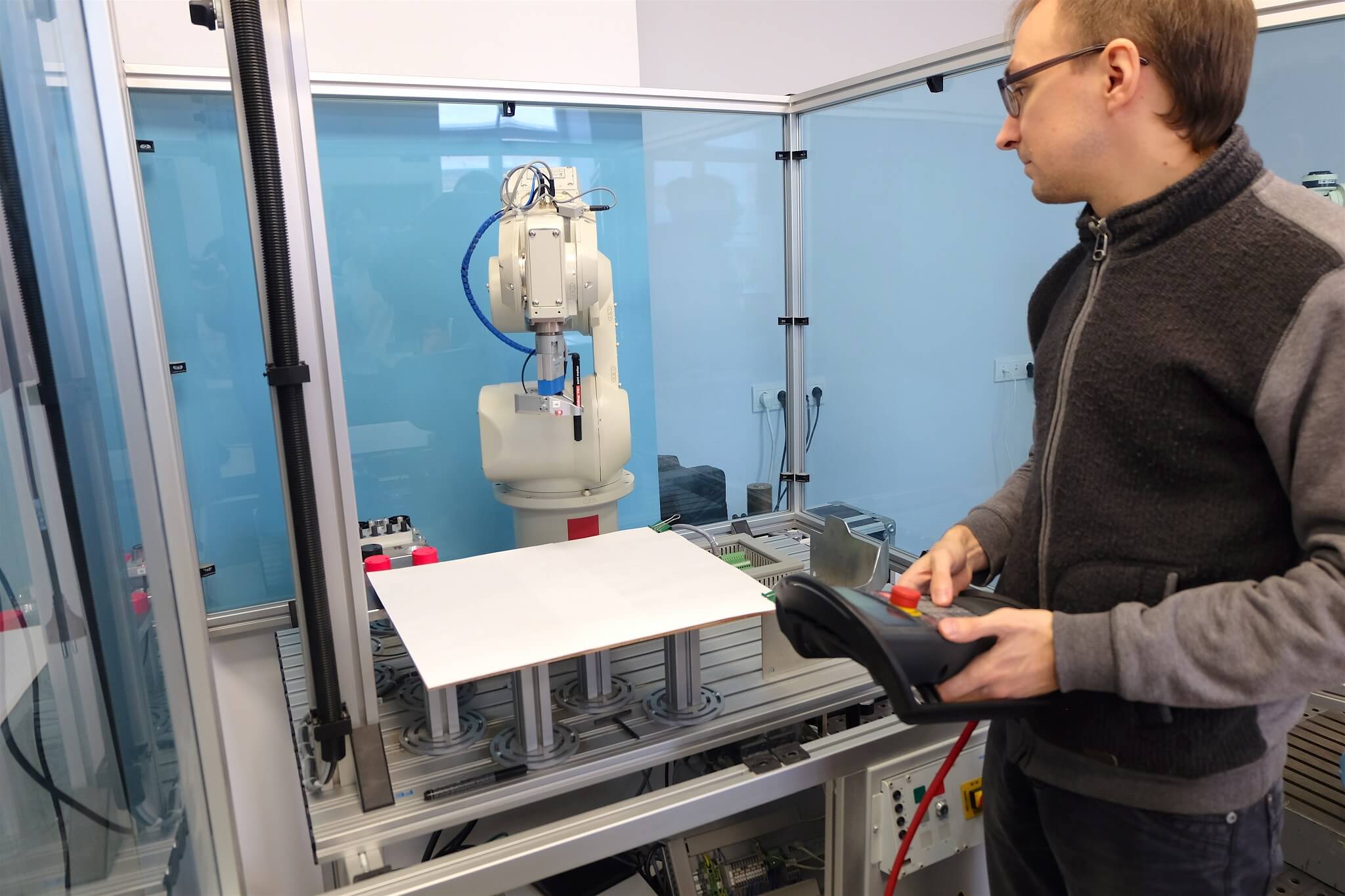

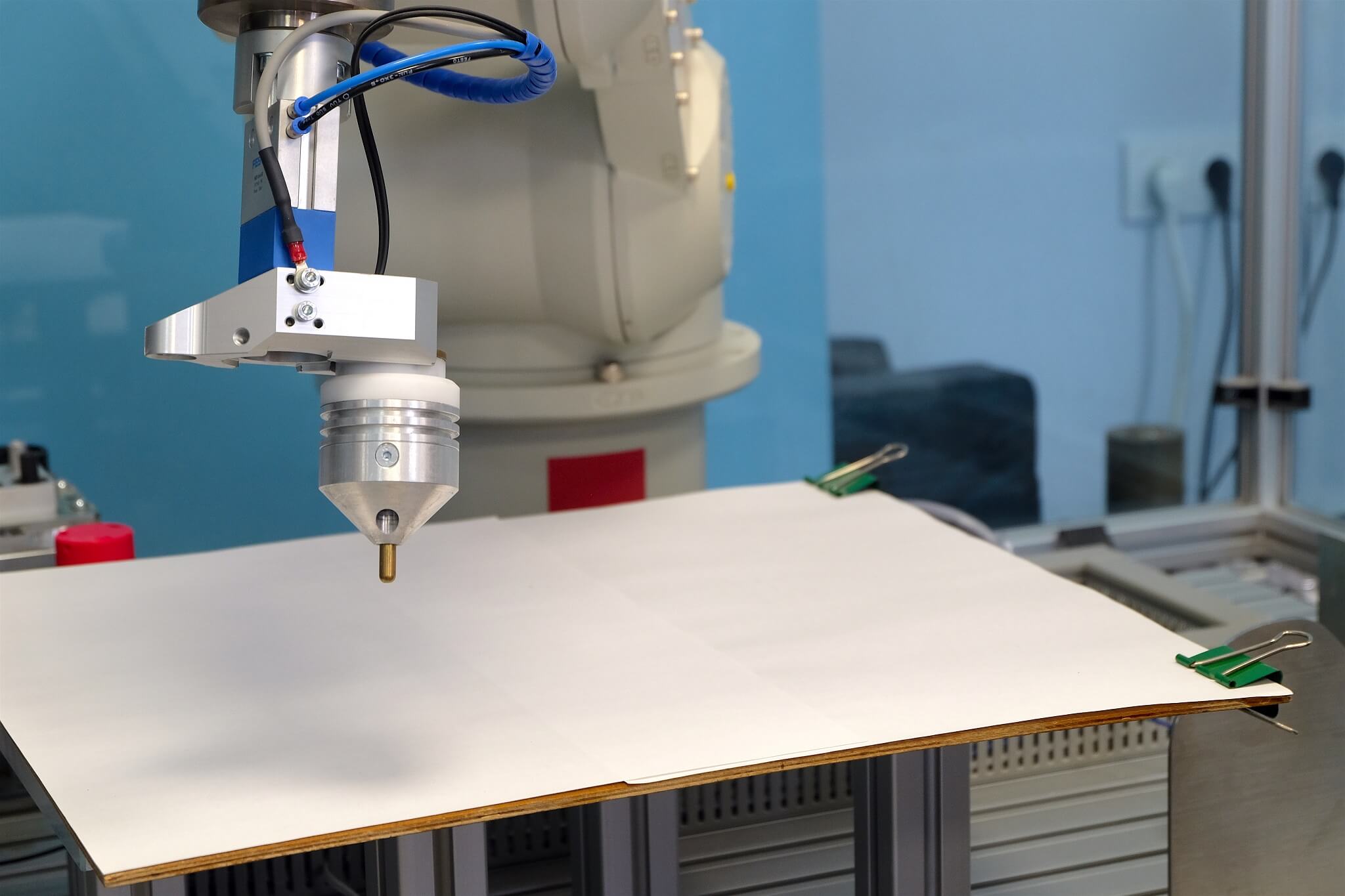

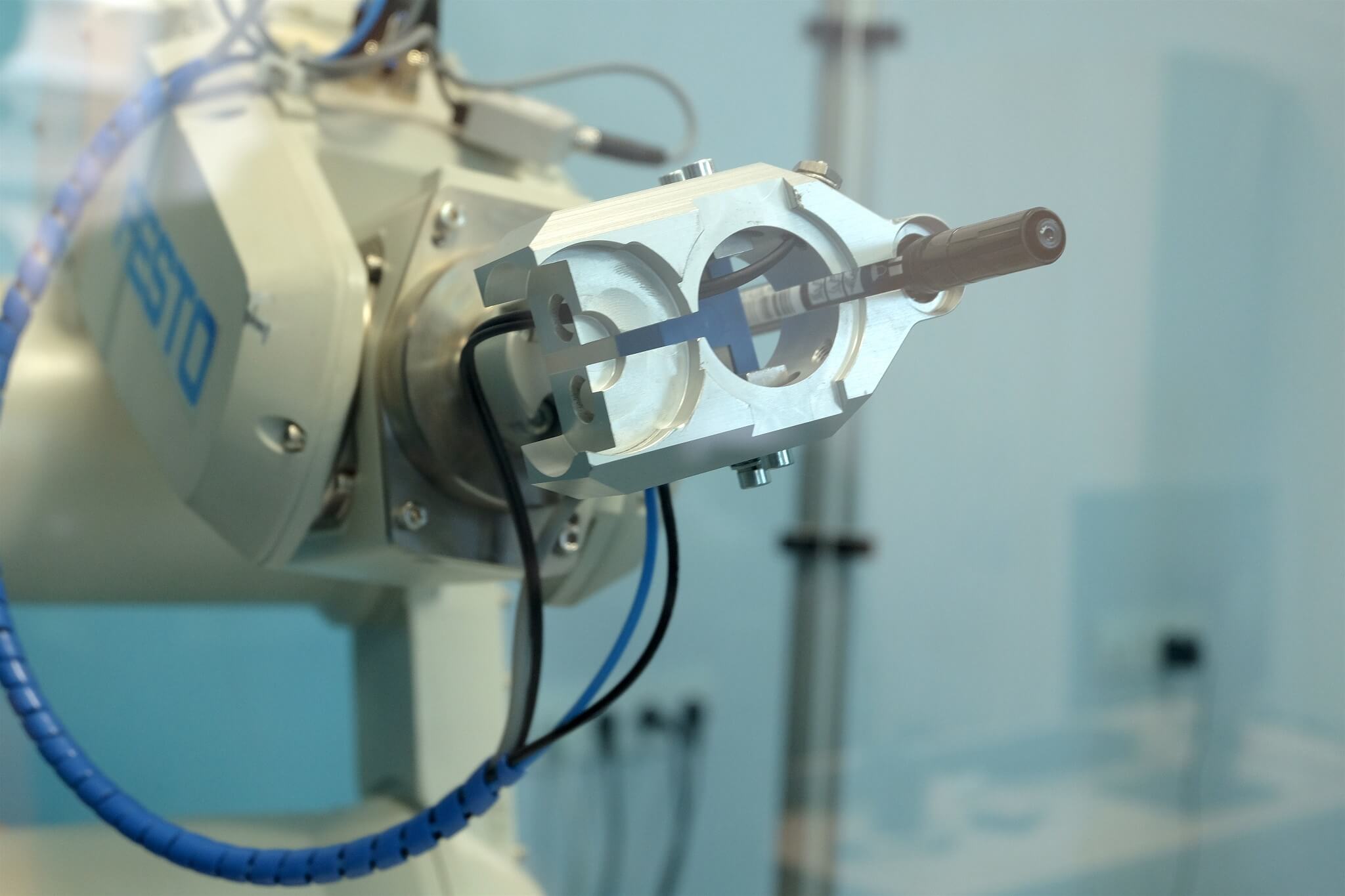

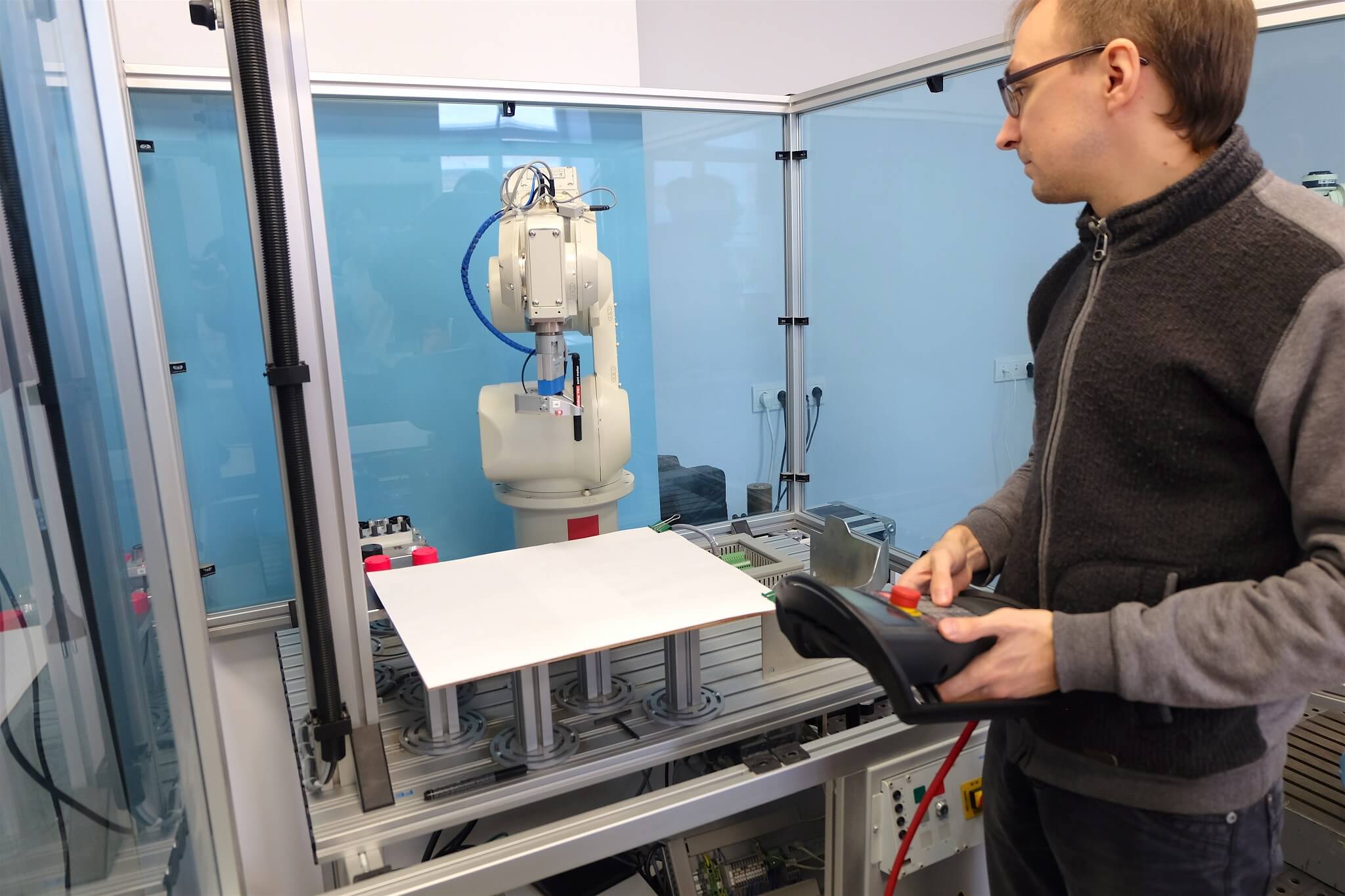

The FESTO Robot Vision Cell is capable of simulating many industrial processes. For example, in this video a member of our staff is simulating a welding task by programming the robot to follow a specific trajectory. The cell is equipped with a machine vision module and can tell thins apart by colour or by shape.

Used in conjunction with the Mitsubishi RV-3SDB industrial robot, the FESTO Robot Vision Cell simplifies the process of robot movement programming. Instead of manually inputting a complex trajectory, you can upload a graphic file. The algorithm automatically detects the shape of the depicted object, calculates the required trajectory, and outputs usable code.

The machine is capable of executing tasks that involve precise movement — from portrait drawing (as seen in this video, where our ‘resident artist’ draws the portrait of Alexander Pushkin with a marker) to complex industrial-grade welding.

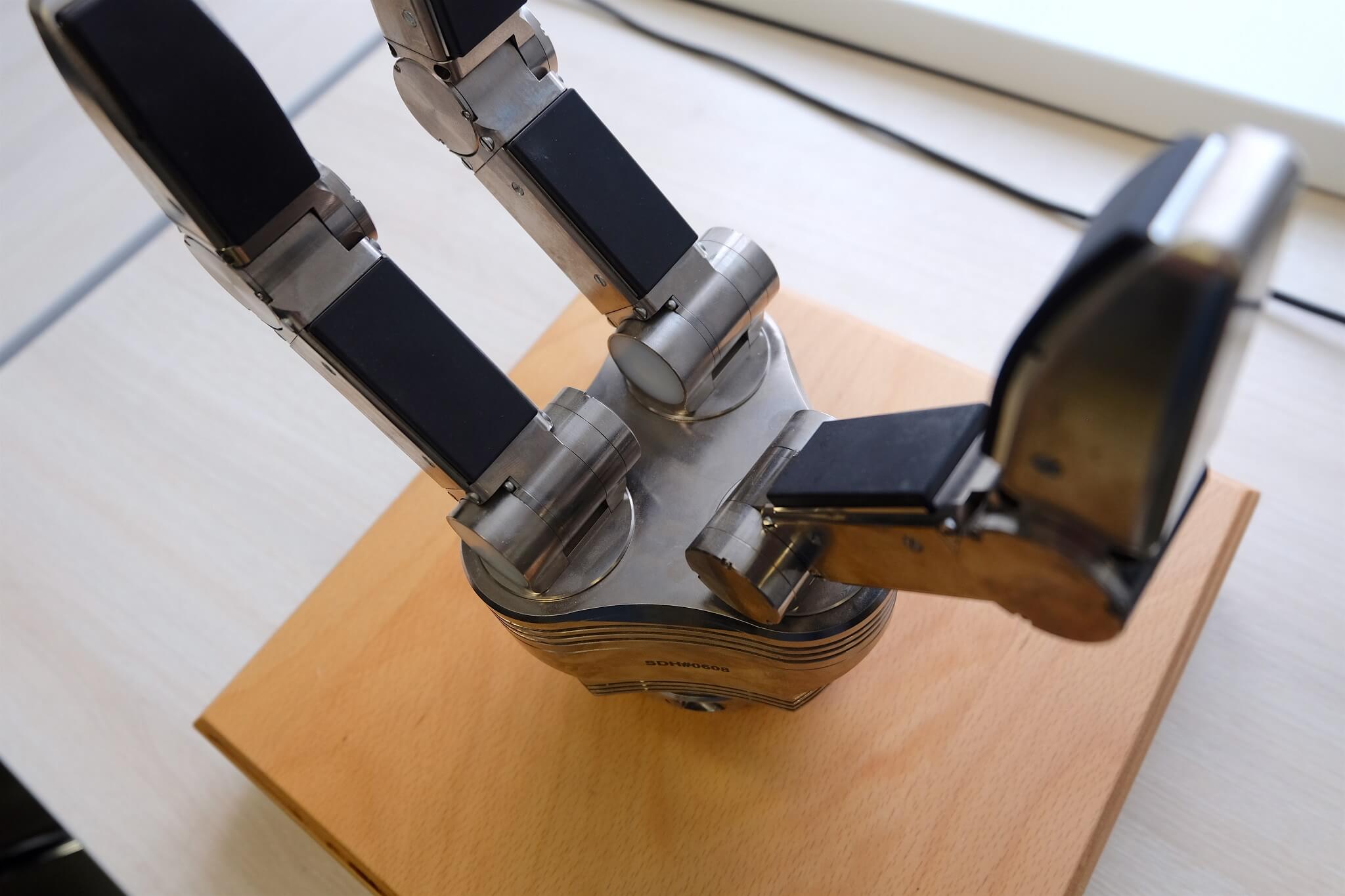

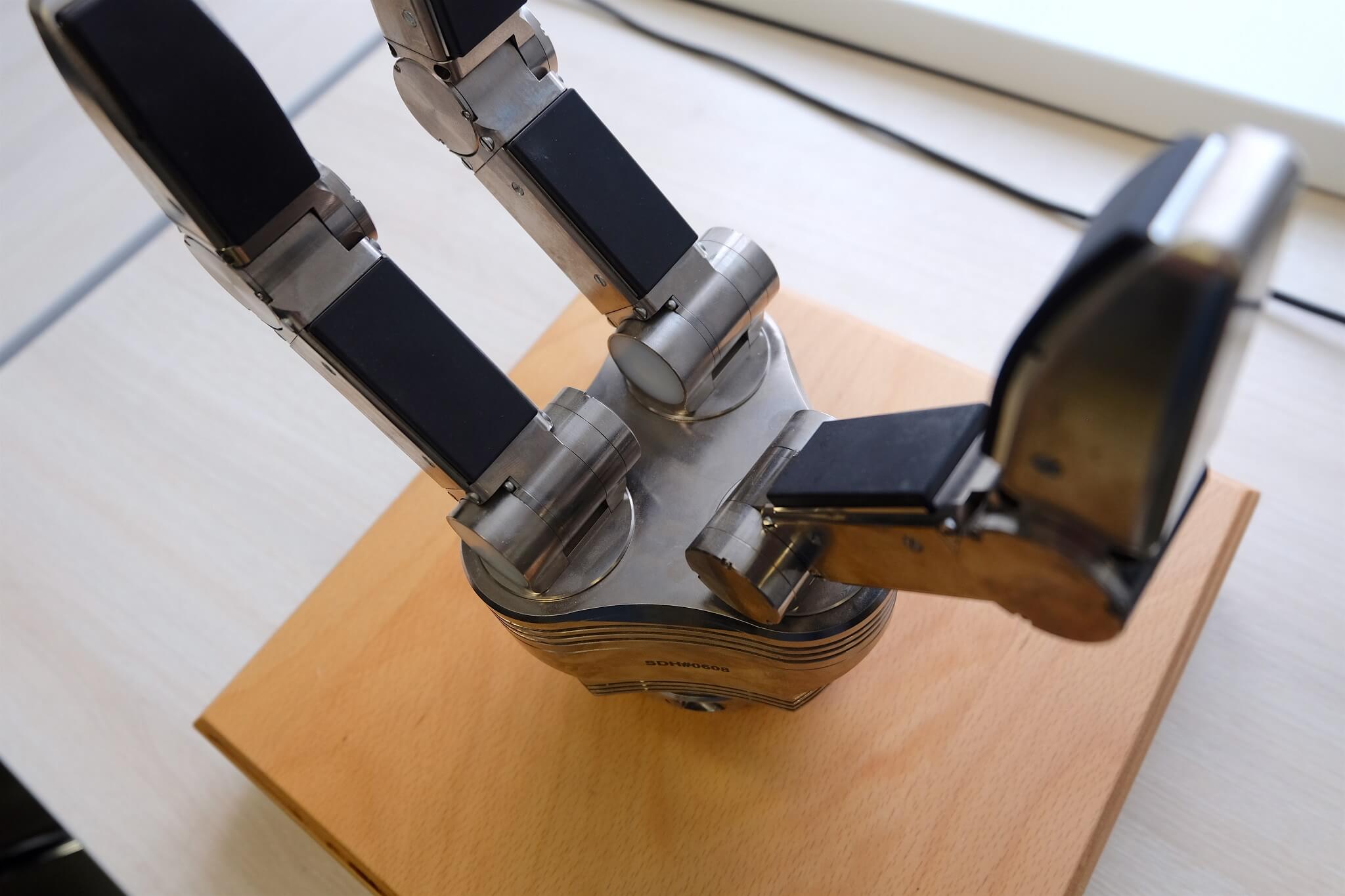

A three-fingered robotic arm with pressure sensors is another highlight of our lab. Such a tool can handle fragile objects other robotic arms would break.

On top of that, we still develop and test dynamic positioning systems — and house a number of remotely controlled semi-autonomous model boats for that purpose.

For now, our indoor lab pool is too small to accommodate larger models, but the smaller boats are deployed right at the lab. Here you can see the process of testing a dynamic positioning algorithm. A small model boat is placed in the centre of the pool, and pushed around. The boat detects the interference and returns to its original position. We’re planning on building a larger pool to enact more complex scenarios.

We previously mentioned our partnership with the British company TRA Robotics. Together we’re developing new algorithms for industrial robot automation. The new generation of fully automated manufacturing plants will be completely controlled by robots and AI — from prototyping to final assembly.

In conjunction with CRSI Elektropribor, a state-owned research center, we are developing mechatronic and robotic systems. Our staff helps them create new software and tools for robot-related tasks. Our staff is working closely with Navis Engineering JSC to help them build dynamic positioning systems for surface vehicles. And, last but not least, we’re partnered with General Motors and InfoWatch. ?

You don’t have to be a student to get a taste of robotics at ITMO University. We operate a youth lab for schoolchildren, where kids can access similar equipment and prepare for international robotics competitions. In 2017, our youth team won the World Robot Olympiad in Costa Rica. The following year, they earned two medals at the All-Russian Robotics Olympiad for schoolchildren. ??We are planning on attracting a greater number of partners, and doing more to promote robotics among the younger generation. Perhaps, their innovations will help take dangerous and repetitive tasks off the hands of factory workers once and for all.

Further reading:

A brief overview

The robotics lab opened its doors in 1955, as the university’s oldest department — the department of computer science and control systems — reached its tenth year of operations. Originally it was used for the development of automated ship testing equipment. Later its staff ventured into cybernetics, CAD and robotics.

Today, the lab staff is primarily preoccupied with the development and enhancement of industrial robots. Man-machine interaction is of particular interest: robots capable of working alongside humans, and new, safer methods of robot control, are being actively developed.

Remote control and online automation systems are also on the lab’s proverbial radar.

Our projects

Some of the lab’s industrial robotic equipment was purchased from large companies. The rest was created in-house, like this 2-DoF Stewart Platform. You can use it (video) to work on balancing algorithms.

The Stewart Platform sports a rectangular sensor-fitted surface the angle of which can be adjusted via USB. It detects and reports back the coordinates of the objects placed upon it. The goal of the operator is to develop an algorithm that keeps the ball in place despite the movement of the surface.

To ensure accurate results, a set of automatic motors compensates for external interference from vibrations or wind. Another lab machine worth mentioning is the KUKA youBot mobile robotic arm.

It was used (video), in conjunction with a digital camera and image processing software, for the testing of object tracking algorithms.

To eliminate outside factors, all external interference is being measured and compensated for. The end result is fascinating — the arm is capable of steadily holding tools and correctly moving them alongside a set trajectory.

The arm was used in an interesting international project. Torque sensors are expensive — so we partnered up with TRA Robotics from the UK to develop a sensor-less torque measurement system. As a result, we can gather data on robotic tools’ interactions with the rest of our equipment without investing extra money or using extra machinery.?

The FESTO Robot Vision Cell is capable of simulating many industrial processes. For example, in this video a member of our staff is simulating a welding task by programming the robot to follow a specific trajectory. The cell is equipped with a machine vision module and can tell thins apart by colour or by shape.

Used in conjunction with the Mitsubishi RV-3SDB industrial robot, the FESTO Robot Vision Cell simplifies the process of robot movement programming. Instead of manually inputting a complex trajectory, you can upload a graphic file. The algorithm automatically detects the shape of the depicted object, calculates the required trajectory, and outputs usable code.

The machine is capable of executing tasks that involve precise movement — from portrait drawing (as seen in this video, where our ‘resident artist’ draws the portrait of Alexander Pushkin with a marker) to complex industrial-grade welding.

A three-fingered robotic arm with pressure sensors is another highlight of our lab. Such a tool can handle fragile objects other robotic arms would break.

On top of that, we still develop and test dynamic positioning systems — and house a number of remotely controlled semi-autonomous model boats for that purpose.

For now, our indoor lab pool is too small to accommodate larger models, but the smaller boats are deployed right at the lab. Here you can see the process of testing a dynamic positioning algorithm. A small model boat is placed in the centre of the pool, and pushed around. The boat detects the interference and returns to its original position. We’re planning on building a larger pool to enact more complex scenarios.

Partners and future plans?

We previously mentioned our partnership with the British company TRA Robotics. Together we’re developing new algorithms for industrial robot automation. The new generation of fully automated manufacturing plants will be completely controlled by robots and AI — from prototyping to final assembly.

In conjunction with CRSI Elektropribor, a state-owned research center, we are developing mechatronic and robotic systems. Our staff helps them create new software and tools for robot-related tasks. Our staff is working closely with Navis Engineering JSC to help them build dynamic positioning systems for surface vehicles. And, last but not least, we’re partnered with General Motors and InfoWatch. ?

You don’t have to be a student to get a taste of robotics at ITMO University. We operate a youth lab for schoolchildren, where kids can access similar equipment and prepare for international robotics competitions. In 2017, our youth team won the World Robot Olympiad in Costa Rica. The following year, they earned two medals at the All-Russian Robotics Olympiad for schoolchildren. ??We are planning on attracting a greater number of partners, and doing more to promote robotics among the younger generation. Perhaps, their innovations will help take dangerous and repetitive tasks off the hands of factory workers once and for all.

Further reading:

- Inside ITMO University: The cyber-physical systems lab

- A tour of the Museum of Optics at ITMO University

- Lab tour: Functional Materials and Devices of Optoelectronics at ITMO University

- Juggling work and study at the Department of Photonics and Optical Information Technology

- Post-cyberpunk: what you need to know about the latest trends in speculative fiction

- Weekend Picks: light reading for STEM majors